Contact

86-539-3101518

86-539-3101518

Fax: 86-539-3101518

Mobile: +86-15969943322

+86-18853986768

Official website: www.xrdplymachine.com

MIC website: http://xrdplymachine.en.made-in-china.com

Email: Jasonqiao@xrdplymachine.com

Factory address: No.1 Zhubao wood industry zone, Lanshan district, Linyi-276000, Shandong,China.

Office: F16, Amethyst mansion, Linyi, Shandong,China.

LOCATION:HOME > PRODUCTS > Wood Veneer Machine > Wood veneer processing machine > Wood veneer processing machine

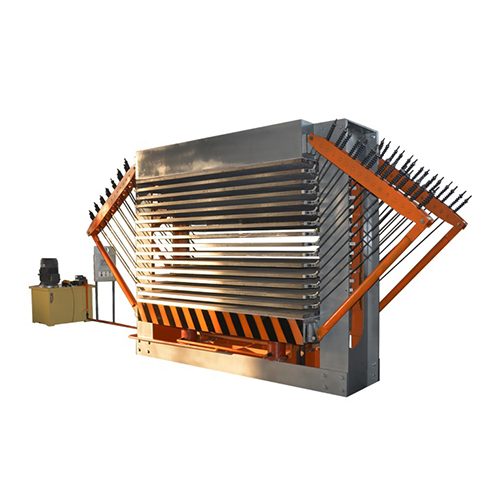

Breathing type veneer hot press dryer

Date: 2022-01-07 15:52

View:

About us:

CHINA XINRUNDE COMPANY is a technology company serving the wood-based panel industry worldwide. Founded in 1989 year and located in worlds biggest wood-based panel production base -- LINYI City, which is famous for manufacturing all kinds of veneer, plywood, blockboard, particle board, LVL, MDF,HDF etc.. Thanks

Date: 2022-01-07 15:52

View:

About us:

CHINA XINRUNDE COMPANY is a technology company serving the wood-based panel industry worldwide. Founded in 1989 year and located in worlds biggest wood-based panel production base -- LINYI City, which is famous for manufacturing all kinds of veneer, plywood, blockboard, particle board, LVL, MDF,HDF etc.. Thanks

Detailed introduction

Through many years' practice and continuous improvment, we introduced newest model veneer drying hot pressing machine with the advantages of much more convenient, high efficience and energy-saving. It is generally used in core veneer's dehumidification, drying an leveling.

Production of plywood veneer dryer is the main equipment.

Just peeling off the veneer moisture content is very high, veneer drying machine is mainly used for drying veneer, which is based on the economy, the loss of the smallest on the plate means to reduce the moisture content of the board to reach process requirements.

Our product has the following advantages:

1. The machine adopts lever spring simultaneous closures system, which makes each core veneer closed simultaneously

2. After special processing, hot platen has a favorable tide exhaust tank on both sides, which makes venner exhause wet gas fast and efficiently.

3. The self-developed PLC systen can set the number and time of exhaust wet gas according to the humidity of core veneer.

4. Oil cylinder is easy to maintain, and also its failure rate is low. Besides, it adopts a upper cylinder mode.

| Model | BY81-4×8/400 |

| Quantity and diameter of Cylinder | 2 unitsΦ320mm |

| Pressure capacity | 400T |

| Cylinder stroke | 800mm |

| Diameter of Lifting Cylinder | Semi-automatic control |

| Hydraulic system compression resistance | 25MPa |

| Main motor | 7.5KW |

| Pressurized motor | 5.5KW |

| Width between nether and top crossbeam | 1700mm |

| Main pump | 100:100 Double-vane pumps |

| Pressurized pump | 10ml/rev plunger pump |

| Hot plate specifications | 2700x1370x40mm |

| Hot plate number | 12--16 |

| Motor Power | 4kw |

| working type | Manual / automatic |

| Maximum working space | 70-100mm |

| Maximum operating pressure | 4Mpa |

| Heating medium | Oil / steam |

| Weight | 4.5t |

Application:

Microwave drying equipment occurred plywood uniform microwave field to make plywood their overall heat, drying process to eliminate the temperature gradient and moisture gradient. Substantially the same as the overall temperature of the plywood. Where the water is discharged from the inside out while the expansion coefficient of contraction consistent plywood, plywood so the drying process to maximize avoid distortion, cracking, dry, carbonation loss, can improve the yield of plywood.

Please fill in your procurement needs and contact information

+86-15969943322

+86-15969943322

Jasonqiao@xrdplymachine.com

Jasonqiao@xrdplymachine.com